INDUCT, AP 500 and AS 200 are solutions designed for the indoor environments remediation from microbial agents, viruses, molds, allergens and odors; these are devices that use PCO technology for the continuous sanitization of air, environments and surfaces.

Induct is a device that can be installed directly inside the all-air ventilation system that guarantees continuous and active sanitization of the indoor environment. Depending on the characteristics of the system (flow rate, duct dimensions, rooms, etc. …), the number and size of the devices to be installed will be estimated.

In fact, Induct is available in the cuts expressed in sq ft (square feet) of the surface of the environment to be treated: 500 – 750 – 2000 – 5000 – 10000. The Ozone generator is integrated in the PCO cell. The air conditioning project is required for the estimate.

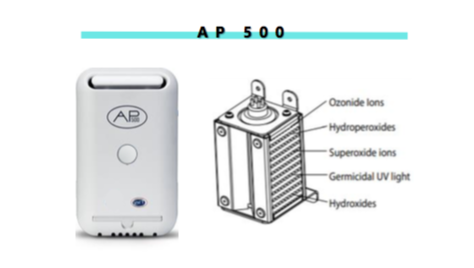

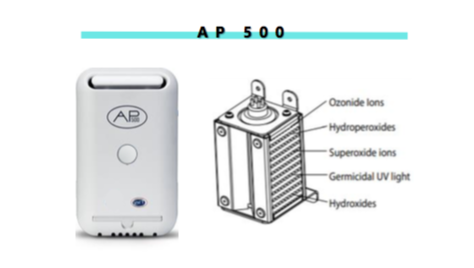

Portable device with integrated ventilation system. AP 500 allows the sanitation of spaces up to 500 sq ft (square feet), or approximately 46 sq m. It is a one-size product.

Main product features:

- 220 V power supply or 12/24 V network with inverter (not included). Estimated consumption: 13 W

- ON / OFF switch

- Dimensions: 15,5 x 30 x 10 cm

Weight: 1.3 kg

Equipped with an integrated ventilation system, AS 200 allows you to sanitize up to 3000 sq ft (square feet), or approximately 279 sq m.

It is a one-size product. Main features:

- 220 V power Estimated consumption: 70 W

- Adjustable ventilation fan and remote control

- AWAY mode for «super sanitization» with Ozone

- Dimensions: 30.5 x 23 x 30.5 cm

- Weight: 4.6 kg

The PCO technology

The PCO (PhotoCatalytic Oxidation) technology, was produced in the mid-90s by NASA for the sanitization of environments intended for aerospace missions.

The technology imitates and reproduces what occurs in nature through photocatalysis: this process, thanks to the combined action of UV rays from the sun, moisture present in the air and some noble metals present in nature, generates oxidizing ions capable of destroy most pollutants and toxic substances.

The photochemical reaction that is generated therefore allows to destroy polluting substances, in particular bacteria, viruses, molds, allergens and odors, with a natural active principle.

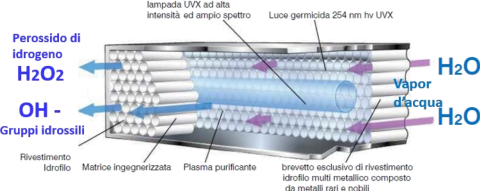

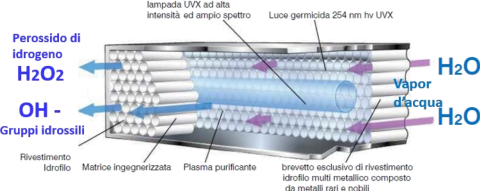

The PCO technology of the products, uses the combined action of a special UV bulb rays and a catalyst structure consisting of a metal alloy with a honeycomb matrix, mainly composed of TiO2 (titanium dioxide) and other noble metals.

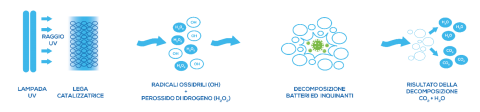

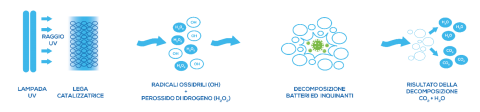

The picture below exemplifies the operation process of photocatalytic oxidation (PCO) technology.

- The air flow laden with humidity, carried by the ventilation system, passes through the module composed of the metal alloy

- A photochemical oxidation reaction starts thanks to the action of a high intensity UV lamp, producing hydroxyl radicals (OH) and hydrogen peroxide (H2O2)

- Bacteria and pollutants decomposition through oxidation reactions and virus inactivation increasing the oxygen level

- Spreading into the surrounding environment and depositing on the surfaces, hydrogen peroxide allows the safe, effective and complete sanitization of the surfaces of the ducts, of the air and, by fall, also of the surfaces of the treated rooms and any fabrics.

Why «active sanitation»?

The proposed active sanitization system differs from passive sanitization systems (traditional filtration, classic ionization, germicidal lamps) in that, thanks to the oxidizing agents generated by PCO technology, there is a sanitizing effect not only at the point where the device is installed but also on the surfaces of the environment affected by the air flow and in the entire aeraulic circuit.

It’s possible to install our products both in the A.H.U. that in the ducts of the all-air system downstream of the fan, so that the air flow invests and passes correctly through the unit

Download the complete Brochure

Products for air sanitation are offered in partnership with Saba Technology Srl